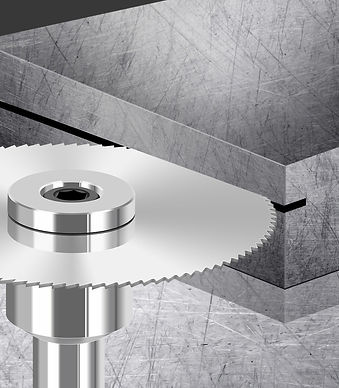

¿Qué son las Sierras circulares de metal duro integral?

La sierra de corte de carburo sólido está hecha de material de carburo sólido (también llamado “carburo cementado” o “acero de tungsteno”) en su totalidad y se utiliza principalmente para producir ranuras y cortes de precisión con fresadoras CNC.

¿Por qué carburo?

En comparación con el material HSS, las hojas de sierra de carburo para metal ofrecen una mayor vida útil de la herramienta y tiempos de ciclo más cortos. Además, presentan una alta dureza y una larga vida útil, lo que permite un fresado de alta velocidad y una alta eficiencia de procesamiento. Las ranuras fresadas son dimensionalmente precisas y tienen un buen acabado, lo que resulta en una alta calidad del producto. Se pueden utilizar ampliamente para el fresado y ranurado de madera, cobre, aluminio y otros materiales difíciles de mecanizar, como acero común, acero endurecido, acero para rodamientos, acero inoxidable, aleaciones de titanio, etc.

¿Qué material se puede cortar con hojas de sierra de corte?

-

Aluminio y aleaciones de aluminio

-

Aleaciones de cobre, latón y bronce

-

Otras aleaciones de metales no ferrosos

-

Madera/Plásticos no metálicos

-

Acero común

-

Acero templado

-

Hierro fundido

-

Aleación de titanio

Sierra circular de corte de carburo serie ToolingBox TC10/TC20

Según las diferentes aplicaciones, ToolingBox suministra cortadoras circulares de corte longitudinal de la serie TC10/TC20 con materiales de carburo sólido a clientes de diversas industrias, como la carpintería, la maquinaria, la industria ligera, la ferretería, los circuitos impresos y la industria del vidrio, entre otras. La serie TC10 está diseñada para el corte de madera, plástico y metales no ferrosos, mientras que la serie TC20 está diseñada para el corte de acero. Si tiene alguna pregunta sobre nuestras cuchillas de corte longitudinal, no dude en contactarnos.

Por que nosotros?

QUIÉNES SOMOS

Nos apasiona ofrecer a nuestros clientes sierras de corte de carburo sólido de alta calidad, desde la materia prima hasta el producto final, y nos comprometemos a resolver los problemas de ranurado y corte. Hoy, ToolingBox se enorgullece de contar con un equipo profesional con una experiencia promedio de 20 años. Le acompañaremos desde el diseño, la producción y el reafilado hasta la aplicación final.

WHY US?

Las ventajas de nuestras sierras de corte de carburo

Piezas en bruto de carburo de alta calidad

Fabricado con piezas en bruto de carburo de alta calidad, herramienta duradera y de larga vida útil.

Afilado dentado

El ángulo de los dientes está especialmente diseñado y el proceso de pulido hace que los dientes sean más afilados.

Acabado de doble espejo

La superficie de la hoja de sierra es lisa dentro de una pequeña tolerancia para mantener la calidad de corte y una alta eficiencia.

Múltiples opciones de especificación

Paso grueso y fino con tamaños en pulgadas y métricos, se pueden ofrecer diferentes espesores

Caso de uso y aplicación de sierras de corte de carburo

1. Comparación de sierras de corte HSS y de carburo

El caso muestra que al cortar materiales abrasivos como hierro fundido o aleaciones de aluminio y silicio (Si > 10%), la vida útil de la herramienta de las sierras de corte de carburo puede alcanzar de 8 a 10 veces la de una hoja de sierra de corte equivalente en HSS; también el tiempo del ciclo de mecanizado se reducirá a 1/4 del de las sierras de corte HSS.

2. Caso de uso de la sierra de corte de carburo

El caso muestra que las sierras de corte de carburo de la serie ToolingBox TC20 pueden alcanzar una vida útil de herramienta muy buena (aproximadamente 200 ranuras) con una velocidad de corte razonable (80 m/min) al cortar la parte del eje de acero de aleación.

Pasos de selección de sierras de corte de carburo

01

Seleccione el diámetro exterior

Generalmente, el diámetro exterior se selecciona por la profundidad de corte (Tabla 1).

03

Determinar el espesor

Determinar el espesor de la hoja de sierra según las necesidades de corte (Tabla 2)

02

Seleccione el diámetro interior

Encuentra el orificio interior correspondiente según el diámetro exterior (Tabla 2)

04

¿Paso grueso o fino?

Si trabaja con metales no ferrosos, ToolingBox sugiere sierras de paso grueso y sierras de paso más fino para metales ferrosos.

*Dia Sizes larger than 100mm need to be customized!

Tooth Forms and Tooth Geometry:

Tooth form A with face similar DIN 1837 (fine teeth) ;

For low cutting depths, slots and thin-walled tubes with small diameter and for short broken chips.

Tooth form B with face similar DIN 1838 (large teeth) ;

For solid material, deep cuts, tubes with wall thickness above 2,5 mm and long broken chips.

Contáctenos directamente para obtener una cotización para una consulta B2B o ventas al por mayor.